Thousands of years ago, fermented foods came from accidentally contaminated food by various microorganisms ever since people have been using starter culture to prepare and preserve food products. The 19th-century work of Louis Pasteur has aided our understanding of the function of starting cultures in various fermentation procedures. In 1892, Hansen began to sell the first commercial starter culture for dairy industries. Since then, those traditional techniques have been altered to ferment every type of food and beverage.

A starter culture is a microbial preparation containing one or more microorganisms that produce different enzymes, such as lactase, proteases, peptidase, and lipases, to facilitate the rate of a chemical reaction and are mixed with the fermenting compound in order to speed up and control the fermentation process.

Though fermentation products can be produced without starter culture, the addition of this culture can improve the nutritional value, enhance the preservation, raise the economic status and modify the sensory characteristics with consistent product qualities. The starter microbes can vary significantly in their morphology, size, manner of reproduction, and ability to break down carbohydrates.

Table of Contents

Characteristics of Starter Culture

The ideal starting culture has the qualities listed below:

- Starter culture produces strong and consistent lactic acid.

- It quickly grows when supplied with the proper organic ingredients.

- It transforms quickly in a changeable environment.

- Viable during production and storage.

- It undergoes acidification and possesses the capacity to use lactose.

- It possesses stable genetic traits.

Types of Starter Culture

Starter cultures are classified into various categories based on different requirements and characteristics like strain, state, temperature requirement, producing flavor, and end products produced.

Based on the strain

Starter cultures are categorized based on strain into the following groups:

- Single-strain culture: It consists of one type of pure culture, such as Lactococcus lactis subsp. lactis. Demerit-it is easily susceptible to phages and can fail to produce desired products. Used in the production of yogourt.

- Multi-strain culture: In this culture, strains of the same microbes are subjected, such as L.lactis and L. lactis subsp. diacetilactis. These strains have expected qualities, and behaviors and are used in the production of continental cheese.

- Mixed strain culture: It is a composite of more than two types of a strain belonging to unrelated species. The microbes used in this culture are Lactococcus lactis subsp. lactis, Lactococcus lactis subsp. cremoris, and gas and aroma-producing mesophilic LAB (Lactic Acid Bacteria) such as Leuconostoc spp. Mixed starters are regarded as safe since they continue to function even if a phage attacks one strain due to their high phage specificity. A further benefit would be a greater tolerance for other conditions, such as variations in temperature and pH. Used for production of sauerkraut, white brine cheese.

Based on the state

Depending on the culture’s state, such as liquid, powder, or frozen, starter cultures are categorized into three types.

- Liquid culture: Starting culture created in a liquid form is known as liquid culture. It is prepared using one of the two different liquid media, i.e., Skim milk/ litmus milk and Non-fat dry milk. Drawbacks- high risk of contamination, rapid strain degradation in mixed cultures, and viability is roughly for a week at 5°C.

- Powder culture: These culture classes are produced by lyophilizing or spraying the liquid cultures to dry them off. Powder cultures can be kept for up to 6 months at 5°C and up to 1 year at -20°C and contain significantly more microbe cells per unit mass than liquid cultures.

- Frozen culture: The bacteria are lyophilized in a frozen state (-20°C to -40°C) to restrict their viability before use. The culture frozen at -45°C can be kept for about three months and a year in liquid nitrogen at -196°C.

Based on the growth temperature

The organisms can multiply their cells number at various temperatures. Based on temperature, the starter culture is divided into the following categories:

- Mesophilic culture: The growth of microbes in this culture ranges from 22-40°C, and the optimum temperature is 30°C. This culture includes organisms like Lactococci. This culture is suitable to produce products like kimchi.

- Thermophilic culture: These cultures have a growth temperature range of 32–45°C, with 40°C being the ideal temperature for growth. This culture contains microbes such as Streptococcus thermophilus, Lactobacillus plantarum, and Lactobacillus delbrueckii subsp bulgaricus. It is suitable for products like yogurt, and mozzarella cheese.

Based on the flavor producer

The organism in the starter culture produces different types of flavors like diacetyl, acetaldehyde, and acetoin. On the basis of the formation of flavor, the starters are grouped into the following types.

- L type: These consist of Leuconostoc spp. as a flavor producer (such as diacetyl). This type of species is typically employed as a starter culture for fermenting products like cheese and kimchi.

- D type: D type contains microbes Lactococcus lactis subsp. diacetylactis strain as both an acid (lactic acid) and flavor producer (diacetyl or its precursor α-acetolactate). This type is mostly used in fermenting dairy products like cheese.

- LD type: It is a mixture of both L and D-type organisms. It is used in the production of gouda cheese

- O type: It doesn’t contain any flavor-producing organism. This type of organism is used to enhance the color of fermented products and also produces antibiotics like bacteriocins. Example: Lactococcus lactis subsp. cremoris. It is preferred in the production of meat products like sausage, and cottage cheese.

Based on the end product

The microorganisms are able to break down the glucose into lactic acid, carbon dioxide, and ethanol/ acetic acid. Based on their ability to utilize glucose, the starter culture is divided into two groups.

- Homofermentative culture: The end product of this culture is lactic acid. The respective microbes used are Lactobacillus delbruckii and Streptococcus faecalis. It is useful in the production of Dairy products like curd, and butter.

- Heterofermentative culture: Glucose is fermented to lactic acid, carbon dioxide, and ethanol/acetic acid. Leuconostoc mesenteroides, Bifidobacterium bifidum. It is used in the production of beer and wine

Source: Techna vet

| S.N. | Food products | Source | Species | pH | Temperature |

| 1. | Curd | Milk | Lactobacillus delbrueckiisspp bulgaricus, Lactococcus sp. | >5 | 37°C-45°C |

| 2. | Tempeh | Soyabean(boiled) | Rhizopus oligoporus | >6 | 35°C-42°C |

| 3. | Natto | Soyabean | Bacillus subtilis | 6-8 | 35°C-40°C |

| 4. | kimchi | Cabbage | Leuconostoc.spp, Lactobacillus spp. | 5-7 | 35°C-40°C |

| 5. | Kefir | Milk | Lb. kefir, Lb.brevis | 4-5 | 2°C-25°C |

| 6. | Ham | Meat | Lb.curvatus,Lb. plantarum | 4-5 | 2°C-30°C |

| 7. | Wine | Grapes | Saccharomyces cerevisae | 2-3 | 25°C-30°C |

| 8. | Cheese | Milk | Lactic Acid Bacteria (LAB), yeast | 3-7 | 20°C-30°C |

| 9. | Cachaca | sugarcane | S.cerevisae, LAB, and other yeast products. | 2-3 | 20°C-30°C |

| 10. | Butter | Milk | Lb. bulgaricum | 4-5 | 35°C-40°C |

| 11. | Salami | Meat | Pediococcus acidilactici | 6-7 | 30°C-40°C |

| 12. | Sauerkraut | Cabbages, Radish | Leuconostocspp, Lactobacillus spp | >5 | 20°C-25°C |

| 13. | Bacon | Meat | Pedicocccus acidilactici, P. pentosaceus | 6-7 | 30°C-40°C |

Preparation of Starter Culture

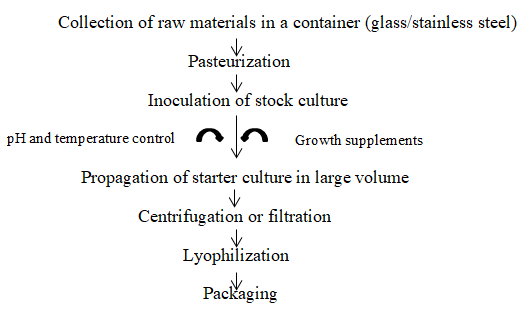

A fine quality can be achieved with the basic guidelines of preparing a starter culture. The nutrient requirement depends on the type of organism used. The nutritional medium often contains beet molasses or cane as a carbon source, ammonium salt, urea, malt sprouts as a nitrogen source, vitamin precursor, inorganic salts, and growth factors.

Temperature and pH may differ depending on the organism used. Unquestionably, the microorganisms of starter culture are chosen based on the product and its properties.

An overview of the preparation of starter culture is shown in the below flowchart:

Preservation of Starter Culture

Starter cultures are preserved in liquid, frozen or dried forms. The following approaches can be made to preserve the starter culture:

- Sub-culturing: The starter culture can be preserved by periodic transfer of organisms in a sterile new media in 2- 3 months intervals. The primary issue with this method is contamination during cell transportation and mutation during cell multiplication.

- Storage at reduced temperature: The cultures are inoculated on agar slopes and kept at -20°C coated with sterile medicinal-grade mineral oil or at -196°C in liquid nitrogen and re-suspended in cryo-protectant (10% glycerol) to prevent cell damage brought on by the development of ice crystals. These cells can be preserved for six months to 1 year.

- Storage in the dehydrated form: The inoculated culture in sterile, moist soil is left to grow for a few days and then to dry at room temperature for about two weeks. This method has been widely used to store and preserve fungi and actinomycetes

- Lyophilization: This method involves growing the culture to its maximal stationary phase. Cells are re-suspended using a protective media such as milk, serum, or sodium glutamate. An ampoule containing a small amount of the suspension is then put in a high vacuum and frozen until the sublimation is finished. Next, the ampoule is sealed. If maintained in a refrigerator, the cells in the ampoules survive for up to ten years.

Application of Starter Culture

Starter culture has several uses in various industries. Following are some of the applications of starter culture.

- Starter cultures enable us to manage the fermentation process and produce predictable results since they are tailored to the substrates.

- The use of starter culture as a probiotic is currently given equal priority.

- Starter cultures are used in various food industries, including the dairy industries, for the production of cheese and other fermented dairy products, as well as in the meat industries to make sausage and alcoholic beverages to produce beer and wine.

- It aids in the improvement of flavor, texture, and lactose utilization.

- It can be used as a preservative agent(García-Díez & Saraiva, 2021).

References

- Taskila, S (2017). Industrial production of starter cultures. Starter Cultures in Food Production,79-100. Doi:10.1002/9781118933794.ch5.

- Ravindra P (2015) Advances in bioprocess technology. Advances in Bioprocess Technology, 1–533 pp.

- Material G (n.d.) Activity, Purity, and Preservation of Starters DNA as Genetic Material.

- Sulieman AME (2018) Microbial Starter Cultures. (May): 1–182.

- García-Díez J & Saraiva C (2021) Use of starter cultures in foods from animal origin to improve their safety. International Journal of Environmental Research and Public Health 18(5): 1–25.

- http://dairy-technology.blogspot.com/2014/01/types-of-starters.html

- https://gidavesaglik.net/starter-cultures-history-definition-and-classification/